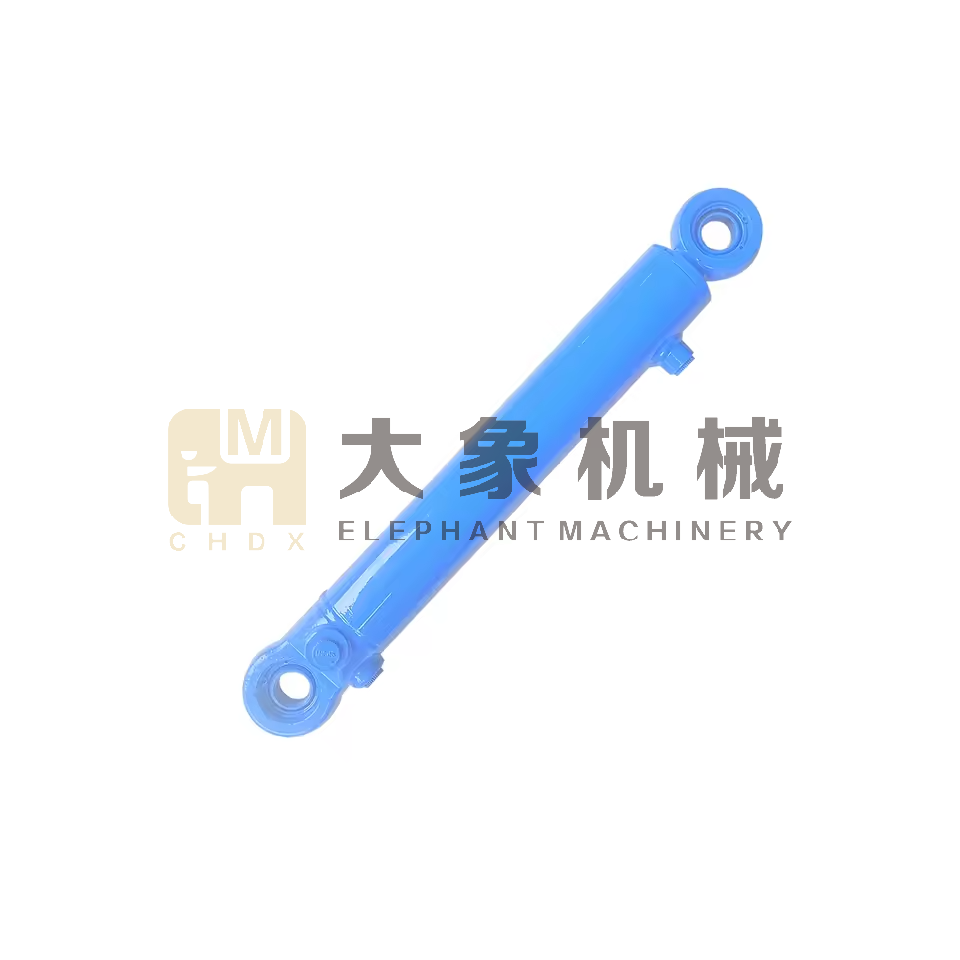

Ultra High Pressure Circle Shift Cylinder Double Acting Customized Oil Pressure Cylinder Digging Long Lasting Hydraulic Cylinder

| Hydraulic Cylinder | Customizable |

|---|

Product Description

Company Profile

Fujian Quanzhou Daxiang Machinery Co., Ltd. is located in the GaoRui Intelligent Equipment Manufacturing Park in Quanzhou, Fujian. We specialize in the R&D and production of hydraulic cylinders, including standard, excavator, and custom non-standard models. Our products serve a wide range of industries such as construction, mining, injection molding, port machinery, metallurgy, and cement equipment, delivering reliable and tailored hydraulic solutions.

DaXiang Machinery has earned the trust of its partners through integrity, capability, and consistent quality. Guided by a customer-first philosophy, we uphold the principles of “Quality Assurance and Heartfelt Service,” offering comprehensive pre-sales support and reliable after-sales service. We warmly welcome customers worldwide to visit us and explore opportunities for cooperation.

Our Factory

Frequently Asked Questions

1. What types of hydraulic cylinders do you manufacture?

We produce a full range of hydraulic cylinders, including double-acting, single-acting, telescopic, plunger, tie-rod, and welded types. Customization is available with bore sizes from 40 mm to 1200 mm and strokes up to 18 meters.

2.What is your production capacity and on-time delivery rate?

3. What materials and components do you use?

We prioritize quality through premium materials and trusted components:

– Cylinder Tubes: 27SiMn, 42CrMo4, ST52, E355; honed or skived & roller burnished.

– Piston Rods: 42CrMo, 40Cr; hard chrome plated (50–100 μm) and optionally induction hardened.

– Seals: From Parker, Hallite, NOK, Trelleborg, or equivalent high-grade Chinese brands.

4. Do you accept custom or OEM orders?

5. What quality certifications do you hold?

6. What is your standard lead time?

Lead times depend on project complexity:

– Samples / Prototypes: 15–25 days

– Standard Orders: 20–30 days

– Large Customized Projects: 35–60 days

Final schedules are confirmed after reviewing order details.

7. How do you ensure quality before shipment?

Every cylinder undergoes strict testing, with full reports provided:

– Pressure test at 1.5× rated pressure

– Complete leakage inspection

– Stroke and speed performance test

– Chrome thickness & hardness verification

– Dimensional inspection against drawings

8. What are your payment terms?

L/C is accepted for orders over US$20,000.

9. Do you provide a warranty?

Yes. We offer a 12–18 month warranty from shipment (or 2000 operating hours). Any confirmed manufacturing defects are replaced free of charge.

10. Which countries do you export to?

11. Can we visit your factory for an audit?

Professional Hydraulic Cylinder Manufacturer